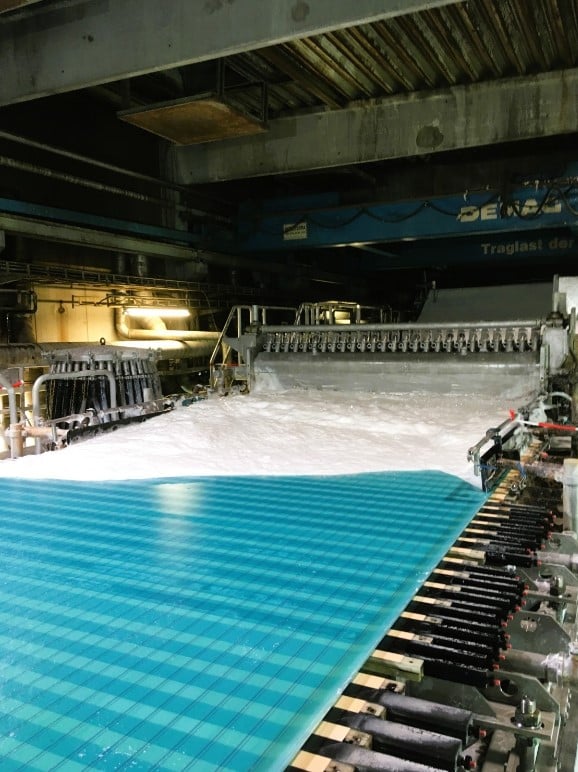

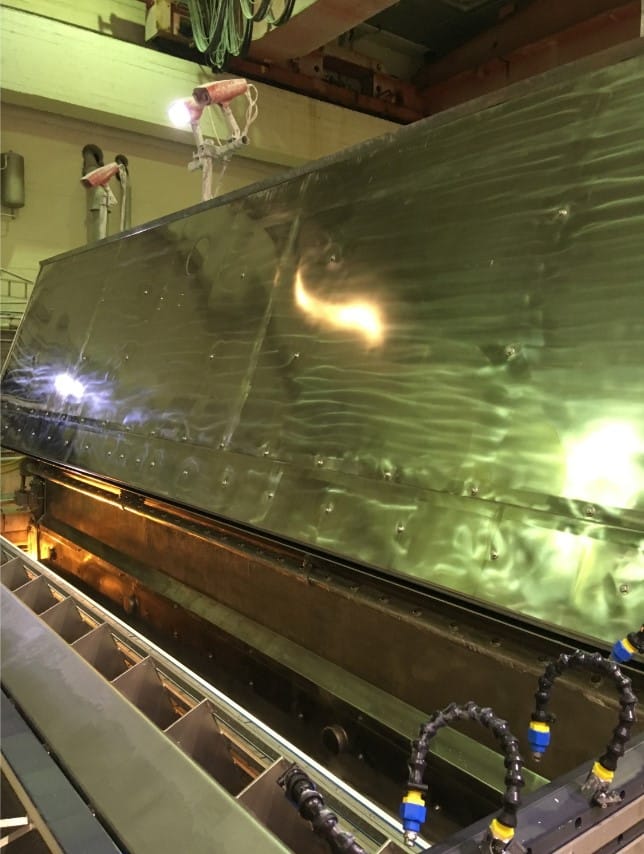

Production equipment in industrial facilities and factories inevitably accumulates dirt over time, including dust, lime deposits, and oil leaks. This buildup can lead to significant issues if not addressed promptly.

Sanna Tiukkanen, Account Manager at Masspap Oy, emphasizes that cleaning dirty industrial equipment is essential not only for occupational safety but also for production efficiency and quality.

Cleaning Agents Don’t Have to Be Hazardous

Industrial facilities often present demanding cleaning challenges. Traditionally, cleaning agents have been harsh chemicals, posing risks to both users and the environment.

Strong acidic and alkaline cleaners often contain corrosive substances, solvents, flammable materials, and toxic surfactants, which can have long-term detrimental effects on waterways and aquatic life.

Fortunately, safer and more environmentally friendly alternatives exist. Masspap uses Hotter GmbH’s cleaning agents, whose surfactants are biodegradable and products are free of solvents and harmful VOCs.

Masspap’s cleaning solutions are significantly safer for both occupational safety and the environment while maintaining excellent effectiveness.

“Our customers are beginning to realize that working with hazardous chemicals doesn’t have to be the norm. If staff safety is a priority when it comes to helmets and vests, why shouldn’t it also apply to cleaning chemical choices?” Tiukkanen adds.

Professional Cleaning Ensures Results

Masspap offers both cleaning products and cleaning services. Their product range is straightforward, with two main types of cleaners:

- Alkaline cleaners for oil and grease.

- Acidic cleaners for lime and carbonate deposits and biological dirt.

“Many of our customers schedule major cleaning tasks with us regularly, while their own staff handle maintenance cleaning in between using our products,” Tiukkanen explains.

Masspap’s experienced team guarantees effective and professional cleaning, making the process seamless for customers. Their familiarity with industrial facilities ensures smooth operations during cleaning.

Foam Cleaning for Efficient Results

The cleaning method and agent are chosen based on the nature of the dirt and the equipment. For water-resistant machinery and environments, Masspap employs foam cleaning, where the cleaning agent is foamed onto the surface, left to act, and then rinsed off.

Foam cleaning progresses faster than traditional water cleaning since the operator can move to the next area while the cleaner works on the surface.

For areas where water cannot be used, dry ice blasting is a safe and efficient method that requires no solvents or chemicals.

Thorough Planning for Effective Cleaning

Industrial cleaning should ideally be scheduled at the beginning of a production shutdown, as warm machinery helps loosen dirt. Clean equipment also simplifies maintenance tasks for technical staff later.

Masspap offers nighttime cleaning to avoid overlapping with other maintenance tasks.

Before starting, Masspap’s team conducts a site survey with the customer to assess the areas to be cleaned, estimated work duration, required cleaning agents, and the optimal time for the job.

“We stay in close communication with the customer throughout the cleaning process. Once the job is completed, we provide a brief report on the work done,” Tiukkanen explains.

Improved Efficiency and Safety

Regular cleaning enhances production efficiency and safety, reduces fire risks, maintains hygiene, and improves the work environment.

Allowing machinery and equipment to accumulate dirt for years—or even decades—is not advisable.

“It’s always rewarding to hear feedback from customers that the job was done well, quickly, and efficiently. The visible improvement in cleanliness benefits both the customer and our team,” Tiukkanen concludes.